On the east coast of Sweden, Telge Elnät distributes electricity to over 50 000 customers with a security of supply reaching 99,99% and continues to focus on large investments targeting a zero-outage policy. Telge Elnät is a customer to dLab since 2019 and below is a scenario describing how dLab’s platform early detected an incipient fault leading to a proactive investigation identifying a faulty component before leading to an outage.

Being able to detect early warnings and act proactively has significant benefits, a fact that has been proven repeatedly by dLab’s platform. By avoiding outages, tangible benefits such as increased customer satisfaction, reduced costs and workplace safety are achieved.

By adopting digital agility and putting some effort into quality management work to benefit from the information provided by dLab’s platform, a more data-driven work approach can easily be obtained where a DSO can act upon identified risks before failure.

Through a controlled remote load shifting, Telge Elnät could quickly pin-point the location of the fault and replace components, components without visible and obvious wear-and-tear patterns. The faulty component was a surge arrestor echoing a unique fingerprint in the analytics from dLab.

“We are keen to always challenge ourselves to achieve a more robust supply of power. There are many things that need to be done, but one important aspect is to start working proactively with maintenance. In this case, where dLab gave us early indications of incipient faults, we were able to work in a more structured, less stressful environment. The result was a successful identification of a faulty component that we were able to replace in time.”, says Lembit Roos, power grid technician.

How did Telge Elnät use the dLab system

During the month of May, high ohmic earth faults and short transient earth faults started to appear frequently on the same feeder and phase in one of Telge’s primary substations, disturbances clearly captured, analyzed, and classified in dLab’s system. The situation continued into June, at which Telge Elnät decided to act. Since they have the possibility to shift loads from one feeder to another, it was decided to open load disconnectors to see whether the recurring fault indications moved from one feeder to another.

By opening different load disconnectors, it was possible to narrow down the position of the fault to a shorter part of the feeder line. When they knew the location of the fault, they inspected that part of the feeder and although there was no obvious visible fault, a fuse holder, two surge arrestors and an old transformer was suspected to be the potential sources of the fault and was therefore replaced. After this the earth fault indications disappeared verifying that the actions taken were successful.

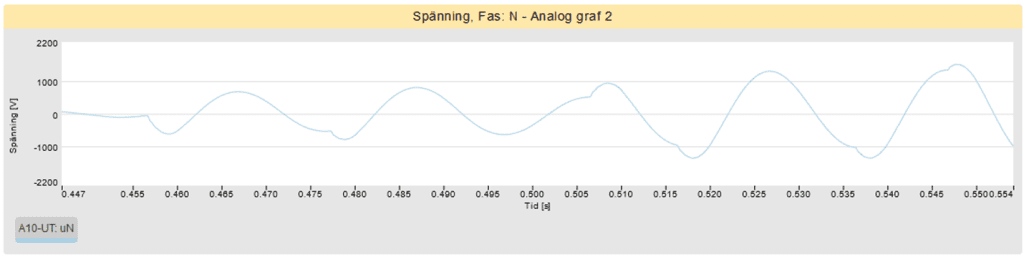

Victor Bagge, power systems engineer at dLab, inspected the current and voltage measurements from dLab’s dAnalyzer and could establish with high probability that the reason for the fault was one or both surge arrestors starting to break down. “As seen in the picture below, there is a recurrent distortion superimposed on the sinusoidal curve, forming a unique fingerprint. This recurring fingerprint on the displacement voltage, indicates that the earth fault is established when the voltage is at its highest level and only lasts for a few milliseconds. The moderate amplitude of each fingerprint indicates a high-ohmic fault when the surge arrestor starts to leak the current through to ground rather than an arc flashover that would create a much steeper spike”, says Victor Bagge.